Sensor Integrating Machine Elements

Your first time working with this wiki? Please read Getting started first!

Interaction of sensor system and machine element

Exemplary measurement tasks in machine elements

Gear

Screw

As one of the most widely used machine elements, the screw offers excellent potential for driving digitalisation through the procurement of data. Therefore, in addition to recording physical quantities that are directly related to the primary function, it is also possible to record a range of other physical quantities. The physical quantities relevant for the primary function are:

- axial force

- torque

- bending torque

Other physical quantities that can be recorded include:

- temperature

- acceleration

- rotational speed

- electric field

- magnetic field

Rolling bearing

Rolling bearings play a central role in the world of machine elements. These inconspicuous yet extremely vital components are indispensable in a wide range of industrial applications, whether in automotive drive systems, wind turbines, huge turbines in power plants or in the precise mechanisms of state-of-the-art robot technology. Rolling bearings enable low-friction movement and transmit forces efficiently, making a significant contribution to the performance and reliability of a wide range of machines.

As digitalization progresses, the integration of digital technologies in a rolling bearing opens up new possibilities for monitoring and optimization. By implementing condition monitoring systems, data can be collected, analyzed and interpreted during operation to monitor the condition of a rolling bearing in real time.

These systems use a variety of sensors to record parameters such as temperature, vibration, lubricant condition and load. In particular, the use of thin-film sensors on the bearing disk of a rolling bearing can be used to detect temperatures or acting forces directly in the effective zone of the bearing. The collected data is then evaluated using algorithms and analysis techniques to detect potential anomalies or deviations from normal operation at an early stage. This allows maintenance intervals to be optimized, downtimes to be minimized and preventive maintenance measures to be planned.

The condition monitoring of rolling bearings is therefore a key element in the predictive maintenance of machines and systems. It enables a proactive approach to maintenance by providing operators and engineers with important insights into the current condition of the bearings. By detecting wear, damage or other problems in good time, expensive repairs can be avoided and the service life of the machines can be extended. In an increasingly digitalized world, condition monitoring therefore plays a crucial role in ensuring the efficiency, reliability and cost-effectiveness of industrial processes.

Gas foil bearing

Gas foil bearings (GFBs) are an advanced class of fluid dynamic bearings that utilize a thin layer of gas, typically air, as a lubricant in a gap between a rotating journal and an elastic metal foil structure, consisting typically of a supporting bump foil and a smooth top foil. This design allows for the creation of a load-bearing gas film at operational speeds, effectively minimizing friction and wear by maintaining separation between the rotor and bearing surfaces through dynamic pressure in the lubrication film. The compliant foil structure enables adaptability to varying operational conditions without the need for tight radial clearances. GFBs are thus able to function at large rotating speeds with high efficiency, low maintenance and without oil and related problems. GFBs are thus particularly suited for applications in high-speed rotating machinery where oil lubrication is undesirable or impractical, including but not limited to fuel cell blowers, air cycle machines, microturbines, and compact compressors.

Despite their advantages, GFBs can be susceptible to strong subharmonic vibrations, similar to those encountered in other hydrodynamic bearings. In addition, they may suffer from thermal instability, leading to unstable operation due to the different thermal expansion of different GFB components. The integration of sensors within GFBs for real-time monitoring of operational conditions will allow controllers to better adress these challenges. The most relevant measurement quantities in this regard include:

- Vibrations

- Temperature (fields) in bearing components and gas film

- Location of the rotor

Further quantities that may be deduced or measured within a GFB include:

- Pressure (fields) in the gas film

- Gas composition, water content

- Rotational velocity of the rotor

- Orbit of the rotor

- Current lubrication regime

Journal bearing

Shaft coupling

Shaft couplings are used to connect two shafts and to transmit torque from one shaft to another. Important features that are of interest for these machine elements are:

- Torque,

- Rotational speed,

- Temperature,

- Shaft misalignment and

- Vibration

An important subclass of couplings are elastic couplings such as jaw couplings. They can be used to compensate for shaft misalignments and can mitigate critical torque shocks. Couplings are ideal components for measuring process data as they are located directly in the power flow.

Splined shaft

Splined shafts are a shaft-hub connection which are used to transmit torque. Important features that are of interest for these machine elements are:

- Torque

- Rotational speed

- Temperature

Key

Seal

Calculation methodology for service life / load carrying capacity

Evaluation method for load carrying capacity

Mechanical integration

Prototypes

Components

Wiring / connectors

Testing / validation

Requirements for test technology

Validation strategy

Cost aspects

Potentials / challenges additive manufacturing

Potentials / challenges heat treatment

Operating strategy

Data handling

Algorithms for reduction

Methods for buffering

Outlook on the use of data

Operating strategy for processors

Validation strategy

Data transfer

Barriers / shielding

Protocols

Microsystem technology

Sensor systems

Overview of physical measuring principles

Temperature

Strain

Acceleration

Acoustic noise

Conductivity / impedance

One way of measuring large strains is to use dielectric elastomer sensors (DES) [1]. They consist out of a dielectric layer which is sandwiched between two compliant electrodes. An electric field will form if an electric potential difference is applied on the two electrodes and a capacitance can be measured. Electrically, DES behave like plate capacitors. A deformation of the DES leads to a change in the capacitance which can then be used to measure the strain or force which caused this deformation.

Resilience

Energy harvesters

Energy storages

Processors (in situ)

Methodology for design of SiME

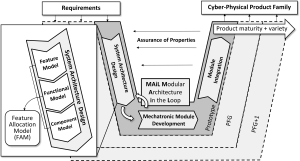

SiME können durch ihre mechanischen, elektrischen und informationstechnischen Komponenten als mechatronische bzw, Cyber-Physische Systeme (CPS) verstanden werden. Die Entwicklung von mechatronischen Systemen kann methodisch unterstützt werden. Die VDI-Richtlinie VDI2206 zum Entwurf mechatronischer Systeme nutzt das V-Modell als zentrales Entwicklungswerkzeug. Im V-Modell werden von den Anforderungen ausgehend disiziplinspezifische Lösungen ausgearbeitet und durch Verifizierungs- und Validierungsaktivitäten in Form von Tests und Simulationen überprüft. Ein auf die Entwicklung von modularen Produktarchitekturen angepasstes V-Modell ist in Abb. ## zu sehen.

Modular system

Die Idee eines Modulbaukastens ist es, Produkte durch die Kombination von Modulen erzeugen zu können. Für SiME bedeutet das, anwendungsfallspezifische Konfigurationen von mikroelektronischen Komponenten zu Sensorsystemen für SiME aufwandsarm erzeugen zu können. Je nach ME und Anwendungsfall werden passende Komponenten und Module ausgewählt und zu einem kompatiblen Gesamtsystem konfiguriert, welches dann ins jeweilige ME bauraum- und funktionsneutral integriert wird.

Abbildung ## zeigt dies schematisch, indem verschiedene ME wie Zahnrad, Kugellager, Schraube oder Passfeder mit einem integrierten Sensorsystem ausgestattet werden und so zum SiME werden. Die Sensorsysteme benötigen dabei Grundbausteine für Ihre Funktionsweise zur Erfüllung ihrer jeweiligen Messaufgabe, einer geeigneten Datenverarbeitung und zum erfolgreichen Energiemangement.

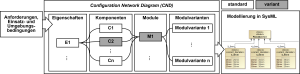

Ein methodisches Vorgehen zur Entwicklung eines konfigurierbaren Modulbaukasten ist schematisch in Abb. ## dargestellt. Das Vorgehen besteht hauptäschlich aus einem Dateneingang und zwei anknüpfenden Methoden. Methode 1 beschreibt dabei die Implementierung von Produktarchitekturen in SysML. Methode 2 beschreibt die Funktionsweise des Konfigurationssystems. Hierbei werden individuelle Produktvarianten auf Basis der verschiedenen Produktarchitekturalternativen erzeugt.

Zur Systemsynthese werden Konfigurationsdiagramme (Configuration Network Diagram) erstellt. Hierbei werden die Produkteigenschaften mit den Komponenten verknüpft und die Komponenten den jeweiligen Modulen zugeordnet. Das ganze kann dann in SysML implementiert werden.

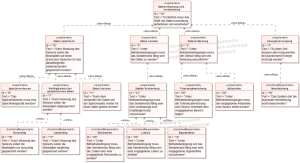

In SysML können separat einzelne Diagramme angefertigt werden, die wie hier zu sehen entlang des V-Modells angeordnet sind. So können verschiedene Diagrammtypen in SysML verwendet werden wie beispielsweise Anforderungs-oder Blockdiagramme, in denen die Produkteigenschaften, Komponenten, Module und Modulvarianten abgebildet werden können. Die einzelnen Diagramme können durch Abhängigkeitsmatrizen verbunden werden. So werden in diesem Fall Anforderungen mit Produkteigenschaften, Eigenschaften mit Komponenten, Komponenten mit Modulen und Module mit Modulvarianten verknüpft. Ein exemplarisches hierarchisches Anforderungsdiagramm ist in Abb. ## dargestellt.

Costs of electronic components

High-quality

Low-quality

Literature

- ↑ Rosset, S., & Shea, H. R. (2016). Small, fast, and tough: Shrinking down integrated elastomer transducers. Applied Physics Reviews, 3(3)